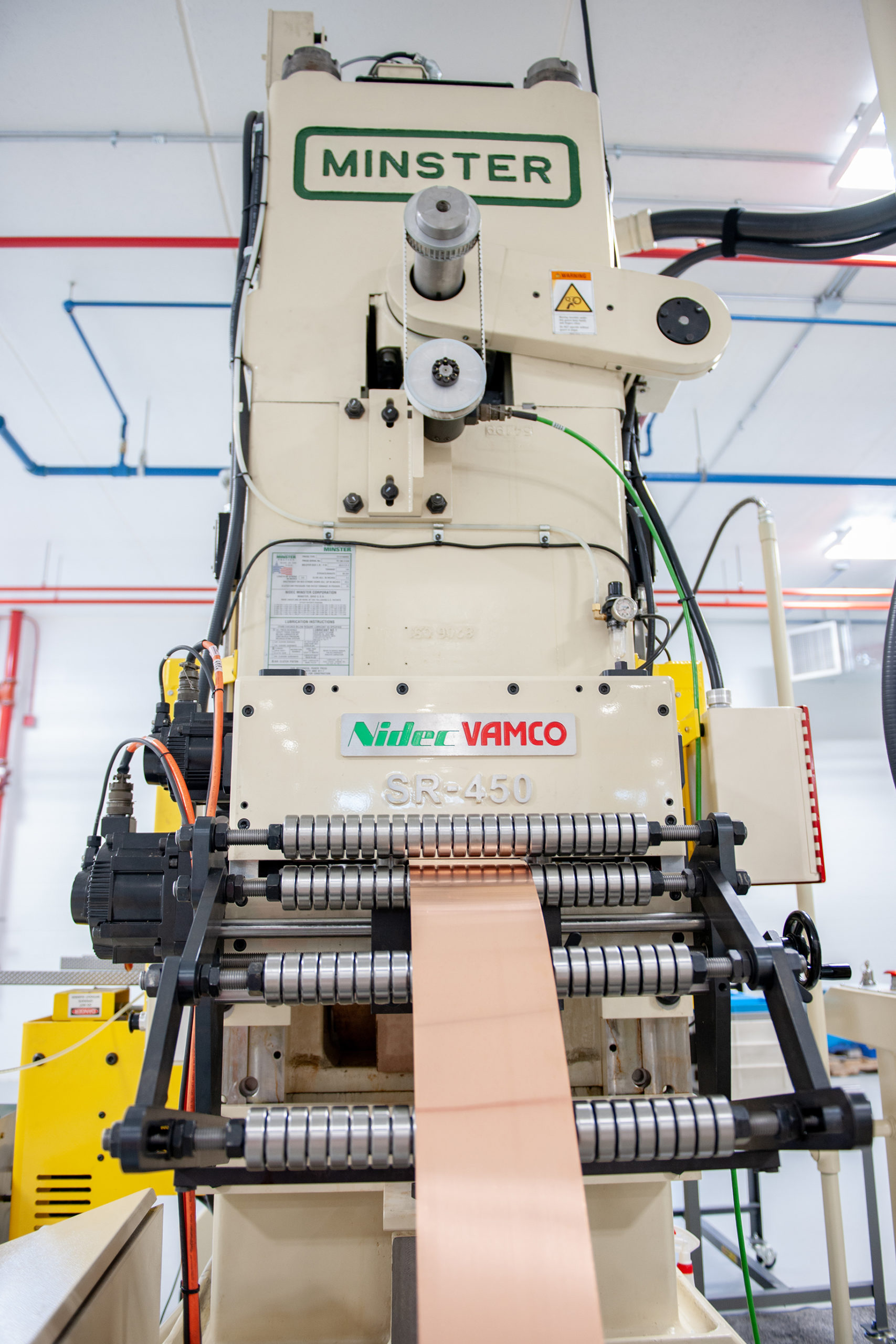

Vamco SR Servo Feeds

Impact part quality, shop productivity and profitability from the beginning of your production processes with Nidec Vamco SR Series feed lines. Designed to consistently perform and withstand the vibration of the most severe stamping applications, the SR series is directly mounted to the press and is electronically cammed to the crankshaft ensuring the highest feeding performance.

Standard Features

• Double axis servo feed (feed rolls & pilot release)

• Electronic camming

• Fully-programmable feed &

release settings

• Powered upper & lower feed rolls

• Push/pull configurations and DHS (3-axis) versions available for increased performance

• Durable cast frame construction

• Advanced monitoring diagnostics

Easy Operation

The SR’s 145mm touchscreen HMI allows users to quickly and easily optimize the following feeding parameters for maximum performance:

• Feed length

• Feed angle

• Roll separation amount

• Roll separation angle

• Material thickness

Once a job is optimized, this data is stored in the SR Series job database for later recall.

Applications Include:

• Motor core laminations

• Electrical connectors

• Lead acid battery grids

• Coin blanks

• Automotive timing chain

• Roller bearing components

• Lead frames

Ideal for High Vibration Applications

Traditionally, metal stamping presses have been equipped with mechanical cam-driven feed units. These mechanisms are powered through the crankshaft of the press and are generally limited in flexibility and require frequent maintenance.

Built to withstand the most abusive metal stamping environments, the SR Series is ideal for high vibration applications including the production of motor cores, automotive chain and bearing components. No application is too severe for its rigid cast frame design. Its economical price makes the SR Series a suitable first step for the transition from mechanical feeder drive units to the powerful world of servo-controlled systems.