A Story of Innovation & Expertise in Pressroom Technology

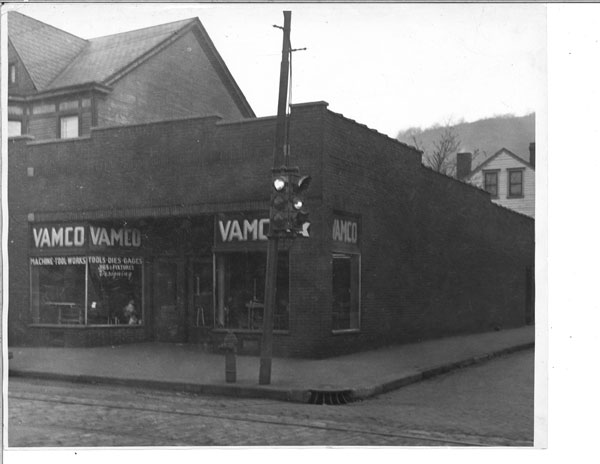

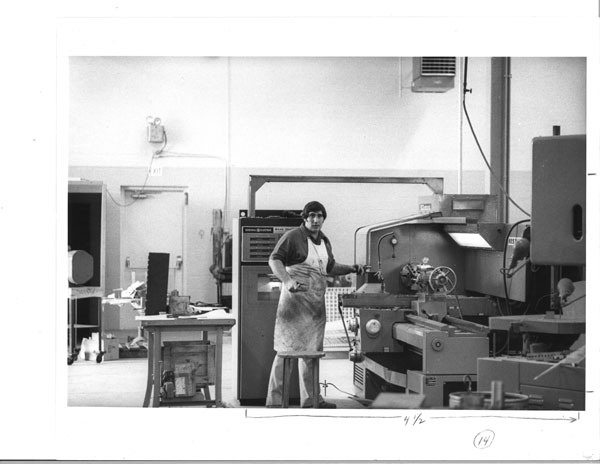

Nidec Vamco was founded as VAMCO Machine & Tool in a small town just north of Pittsburgh, PA, by Patrick J. Gentile in 1945. As an industrial tool maker by trade, Mr. Gentile started and grew his contract manufacturing operation with just a few basic manual machine tools servicing the tool and die industry.

After manufacturing tools and dies for many years, Mr. Gentile successfully developed the world’s first Change Gear Cam Feed for the high-speed metal stamping industry in the late 1960s. This device revolutionized the industry as it substantially reduced the complexity and time associated with the set-up configuration of a press feed. Still in production today, this rugged and highly accurate machine has proven to be one of the finest inventions in the press feeding industry.

As pressroom technology advanced, Vamco evolved as well as Mr. Gentile’s son, Joseph Gentile, invented and introduced the world’s first Adjustable Cam Feed. This machine became a unique patented technology eliminating the mechanical “gear change” required on the aforementioned technology to adjust the feed length setting on the press feed unit.

After nearly 30 years of designing and manufacturing high-speed mechanical cam-driven feeds, Vamco began the research and development of an unprecedented technology known today as the High-Speed Servo Feed in 1992. This feeding system (the Quantum) served as the world’s first fully programmable high-speed electronic roll feed. Its highly advanced technology once again revolutionized the metal stamping industry and eliminated all the mechanical adjustments commonly associated with mechanical cam-driven press feeds.

Furthermore, the Quantum was the first feeding system to provide real-time diagnostic and troubleshooting feedback to the press operators to improve part quality and eliminate lost production. Engineered originally to withstand the abusive conditions associated with the electric motor core stamping industry, Vamco has since created an entire line of Quantum feeding systems serving both the high-speed electrical industry as well as the conventional metal stamping market.

In 2011, Vamco once again redefined the material feeding industry with the introduction of the world’s first High-Speed Servo Gripper Feed known as the Quantum-SG Series. Traditional Gripper Feeds are driven by mechanical cam arrangements that are both complex in design and inflexible for part changeover. The Quantum SG Series provides a mechanically simple solution leading to infinite flexibility and reduced maintenance.

In 2008, Nidec Vamco opened a second manufacturing facility located in Shanghai, China. This highly advanced manufacturing operation also provides the Southeast Asian market with the industry’s highest level of sales, service, and customer support.

In 2017, Nidec Vamco was acquired by Nidec Minster Corporation, a subsidiary of the Nidec Corporation, headquartered in Kyoto, Japan.

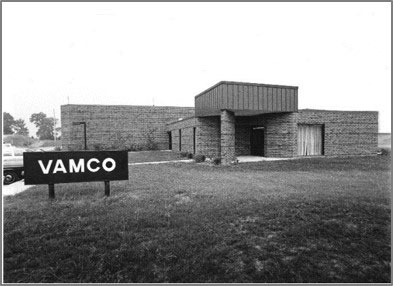

Today, Nidec Vamco’s headquarters are located in the RIDC Industrial Park just north of Pittsburgh, PA, USA. Equipped with the most advanced precision CNC production machine tools, this state-of-the-art facility is staffed by the top engineers in the pressroom equipment design field and by highly qualified machine tool craftsman. They proudly adhere to strict quality control so that Nidec Vamco products can always be labeled as the finest in metal stamping.